The development of a demo intelligent factory

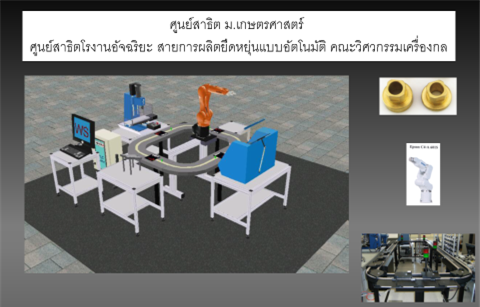

Automated Manufacturing Systems by Computer Integrated Manufacturing (CIM) that can be analysed and processed in production. To make the production process faster and more varied. This type of production system can make modifications of the workpiece as well as change the quantity of production more easily and quickly with the development plan of the area as shown in Fig. 1.

An industry group that fits this demo centre. The manufacturing of spare parts and automotive parts. Electronic Or manufacturing industries. The production line is a production line or mass production or an industry that needs automated production. Examples of plant types that can bring innovation to the demonstration centre.

- Ø Automotive Parts Factory Electronic Parts Manufacturingฃ

- Canned Food Factory

- Ø drinking water plant

- Factory producing different products or products. The production line model.

The demonstration centre can provide training and consulting services or educational services such as learning how to use a demo site, learning how to set up a demo site.

Benefits

- Ø Learn the principles of automated production systems and flexible production.

- Investment guidelines to build automation in their own factories. At low cost

- Ø Design and use of robotic machinery, equipment or tools. It is suitable for their own production automation system.

Place Top floor of Building 5, Department of Mechanical Engineering, Faculty of Engineering Kasetsart University 50 Ngamwongwan Road Lat Yao Chatuchak Bangkok 10900

Area 3x3 square meter

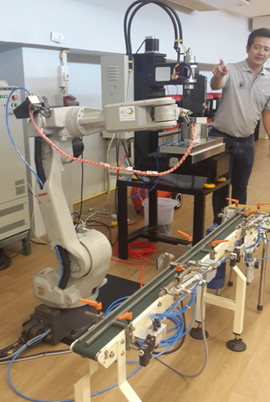

Work Area loading and unloading, installing robotic slides, robots to work stations. (Fig. 2)

This site can accommodate up to 20 people.

Service charge : 10,000 baht / day or 1,000 baht / hour.

Figure 1 the development of the demo area of the demonstration plant.

Figure 2 System loading and unloading, sliding table, robot machine into work station